CNC MANUFACTURING

Reliable CNC Machining Solutions

At Port Welding, we're experienced, dedicated, and honest about our craft. Our CNC machining services deliver consistent, high-quality results through refined processes and a reputation earned one part at a time.

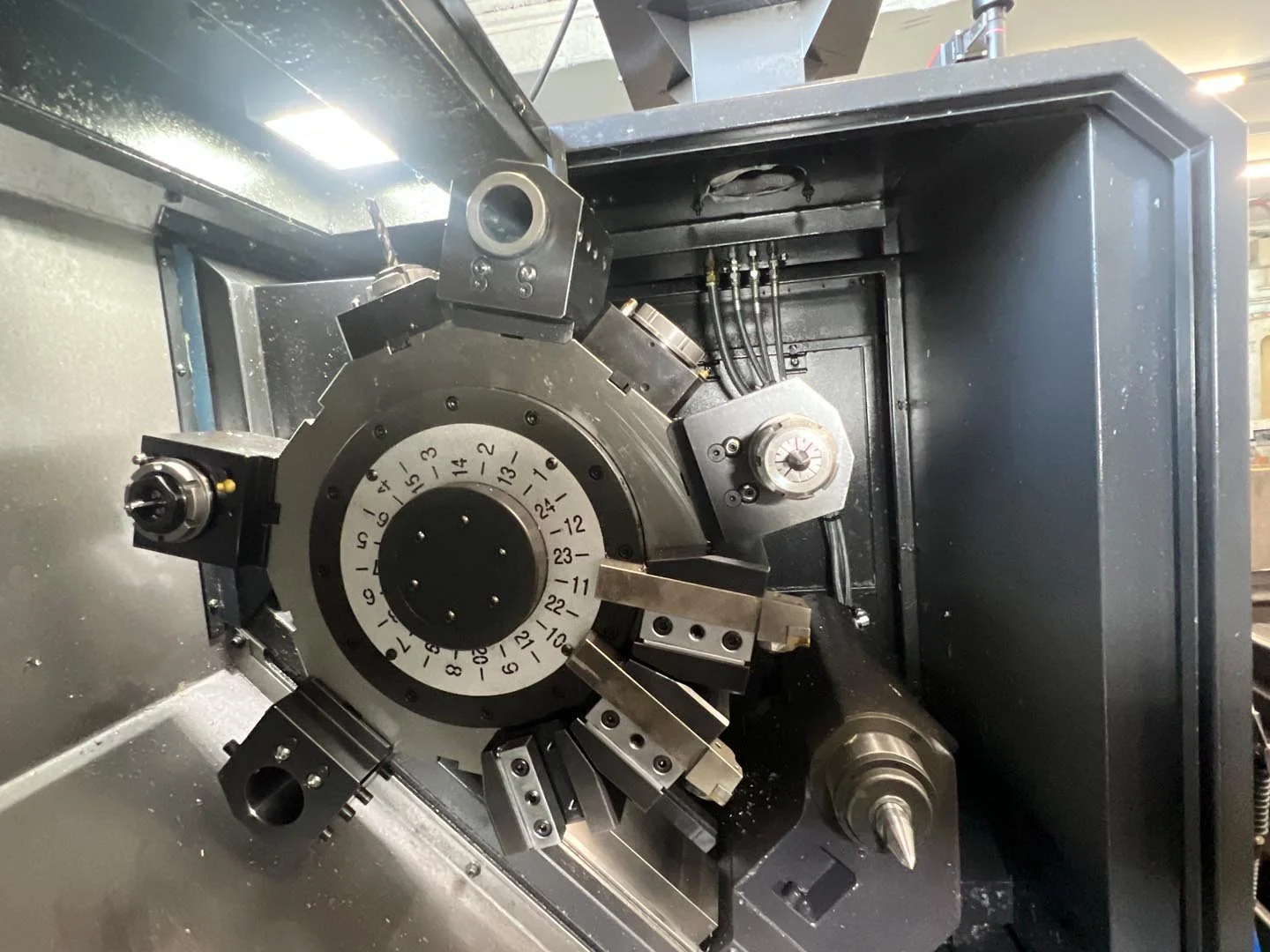

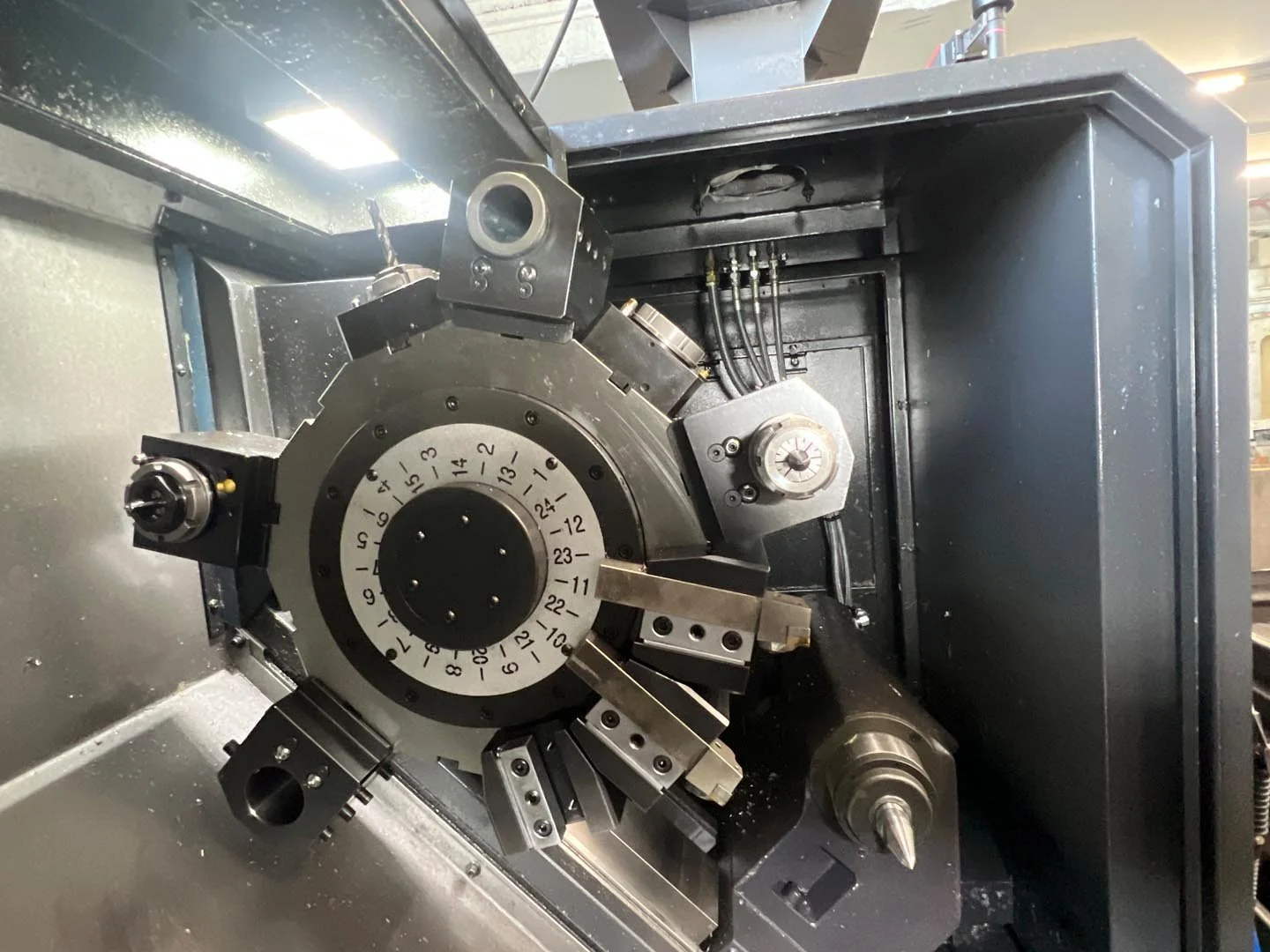

Our state-of-the-art equipment, combined with skilled operators, ensures that great manufacturing comes from experience, attention to detail, and genuine care for the work.

Why Our CNC Approach Works

CNC machining refines parts for perfect fit and function. The multi-tool, automated process offers finished edges and details that demand high tolerances, including bevels and threaded holes. High-volume and high-quality CNC production keeps your contract-manufactured parts on spec, piece by piece.

We combine speed with thoughtful manufacturing. While our equipment is advanced, it's our team's knowledge that makes the difference. We identify potential issues early, adjust processes based on real-world experience, and deliver parts that work consistently. When something needs adjustment, we handle it promptly

What Our CNC Machining Delivers

Working Capacity That Handles Your Projects

Working Area: 100" x 50" punching operation accommodates everything from small components to large-format parts

Maximum Sheet Thickness: Up to 1/4" across various materials including mild steel, stainless steel, and aluminum

Multi-Tool Capabilities

Our CNC punching capabilities allow us to process a diverse range of sheet metal parts with flexibility. The automated tool-switching means we can create various shapes, holes, and features in a single setup—reducing handling time and maintaining consistency throughout your run.

Integrated Operations

Multi-Shear: Clean cuts with smooth edges that typically don't need additional finishing

Multi-Bend: Accurate bends and folds integrated into the punching process

Tapping: Threaded holes created to your specifications

Deburring and Roller Technology: Finished edges that meet your assembly requirements

Benefits of OUR CNC MACHINING

-

Our integrated approach reduces setup time and handling between operations. We're fast because we've streamlined the process, not because we cut corners. When rush jobs come in, we'll tell you what's realistic and deliver on our commitments.

-

Complex hole patterns, custom shapes, tight tolerances—we handle these regularly. Our experience shows in the details: proper material selection, appropriate tooling choices, and realistic timelines that account for real-world manufacturing variables.

-

Experienced programming and careful nesting reduce waste, but we're not wasteful to begin with. We optimize layouts because material costs matter to your bottom line, and efficiency matters to ours.

-

With integrated tools for tapping, deburring, and multi-bending, we complete more operations in-house. This means fewer handoffs, better quality control, and more predictable delivery times.

-

CNC punching makes economic sense for both prototypes and production runs. We price based on actual machine time, material usage, and setup requirements—no hidden fees or surprise charges.