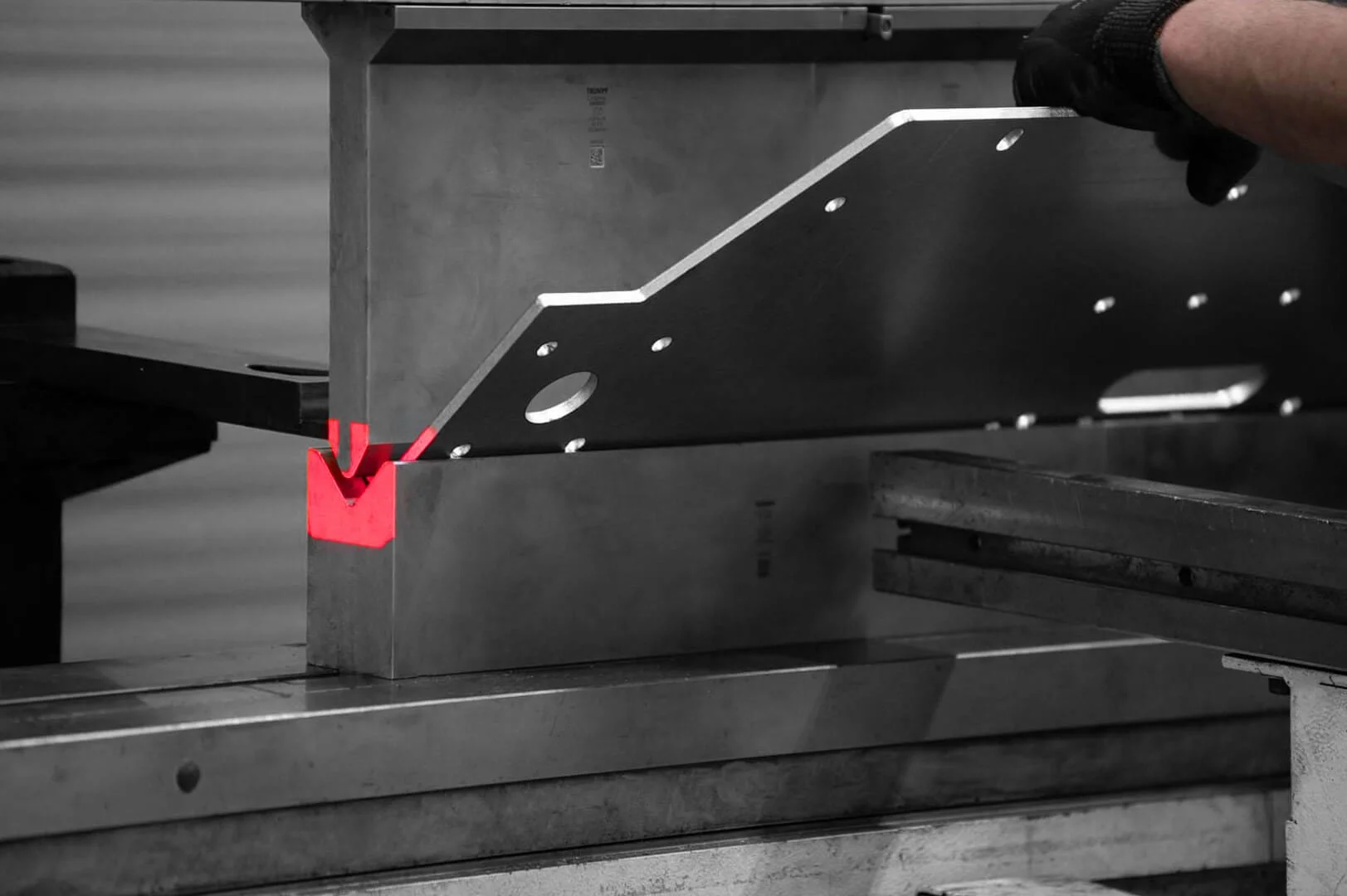

BRAKE FORMING

High-Precision Brake Forming

At Port Welding, we specialize in high-volume brake forming services that provide exceptional accuracy, versatility, and efficiency for a wide variety of sheet metal applications. Using state-of-the-art press brake technology, we deliver consistently accurate bends, complex geometries, and custom profiles to meet the needs of high-volume production and intricate sheet metal fabrication.

Experience Unmatched Accuracy

Why Choose Port Welding for your Brake Forming Project?

Our brake forming services combine speed, precision, and flexibility, providing you the perfect team to bend all varieties of materials, creating complex part geometries for your project.

Our brake forming services combine speed, precision, and flexibility, providing you the perfect team to bend all varieties of materials, creating complex part geometries for your project. Whether you need simple angle bends, multi-stage forms, or custom contours, our press brake team can provide highly reliable results every time. This process eliminates the need for multiple operations by combining advanced forming techniques into one seamless operation, enhancing both efficiency and cost-effectiveness.

Key Features of Our Brake Forming Services:

-

Large Bending Capacity

Our press brakes accommodate sheets up to 240" wide, allowing us to handle both small components and large-format parts with ease. This expansive working area enables us to tackle a wide variety of sheet metal sizes and bending applications.

-

Maximum Sheet Thickness

Our brake forming machines can bend a wide range of sizes, making them ideal for metals like mild steel, stainless steel, aluminum, and other specialty metals. Contact us for more details.

-

Precision Multi-Axis Bending

With our advanced CNC-controlled press brakes, we offer multi-axis bending capabilities, allowing us to perform complex bends with exceptional accuracy and tight tolerances. This versatility enables us to produce parts with intricate geometries and angles while preserving material integrity.

-

Custom Tooling for Complex Shapes

We employ custom tooling and bending dies that allow us to form unique shapes and angles, ensuring the perfect fit for your project. Whether you need simple bends or complex multi-stage profiles, we have the right tooling to deliver precision results.

-

Burr-Free Edges

Our brake forming process produces smooth, burr-free edges, reducing the need for additional post-processing such as deburring and edge finishing, leading to faster turnaround times and a higher-quality end product.

Benefits of Our Brake Forming Services

At Port Welding, our brake forming services provide the ideal balance of speed, precision, and cost-efficiency for your sheet metal fabrication needs. Whether you require a single custom part or high-volume production with strict tolerances, we have the technical expertise and advanced equipment to meet your requirements and deliver exceptional results.

-

Thanks to our automated CNC press brakes, we achieve fast cycle times and reduce manual labor, making brake forming ideal for both low-volume and high-volume production runs.

-

Our brake forming technology allows for complex and precise bending operations, from simple bends to multi-axis geometries, delivering custom parts with tight tolerances that match your exact specifications.

-

The automated nature of our brake forming machines, combined with integrated tooling for various bending functions, ensures that we can meet your project deadlines and deliver parts on time, even for large production volumes.

-

Brake forming is a highly cost-effective solution, especially when scaling up production. By reducing the need for multiple operations and labor-intensive processes, we can offer competitive pricing without compromising quality.

Optimize Your Production with Our Brake Forming Services