HIGH-YIELD LASER CUTTING FOR THE MANUFACTURING INDUSTRY

Port Welding is more than just a manufacturer of high-quality laser cutting, welding, and brake forming – we’re your trusted partner in precision and high-yield production.

Port Welding combines state-of-the-art technology with expert craftsmanship to deliver results that exceed your expectations.

Experience cutting-edge technology and expert craftsmanship.

Let’s make your next project a success.

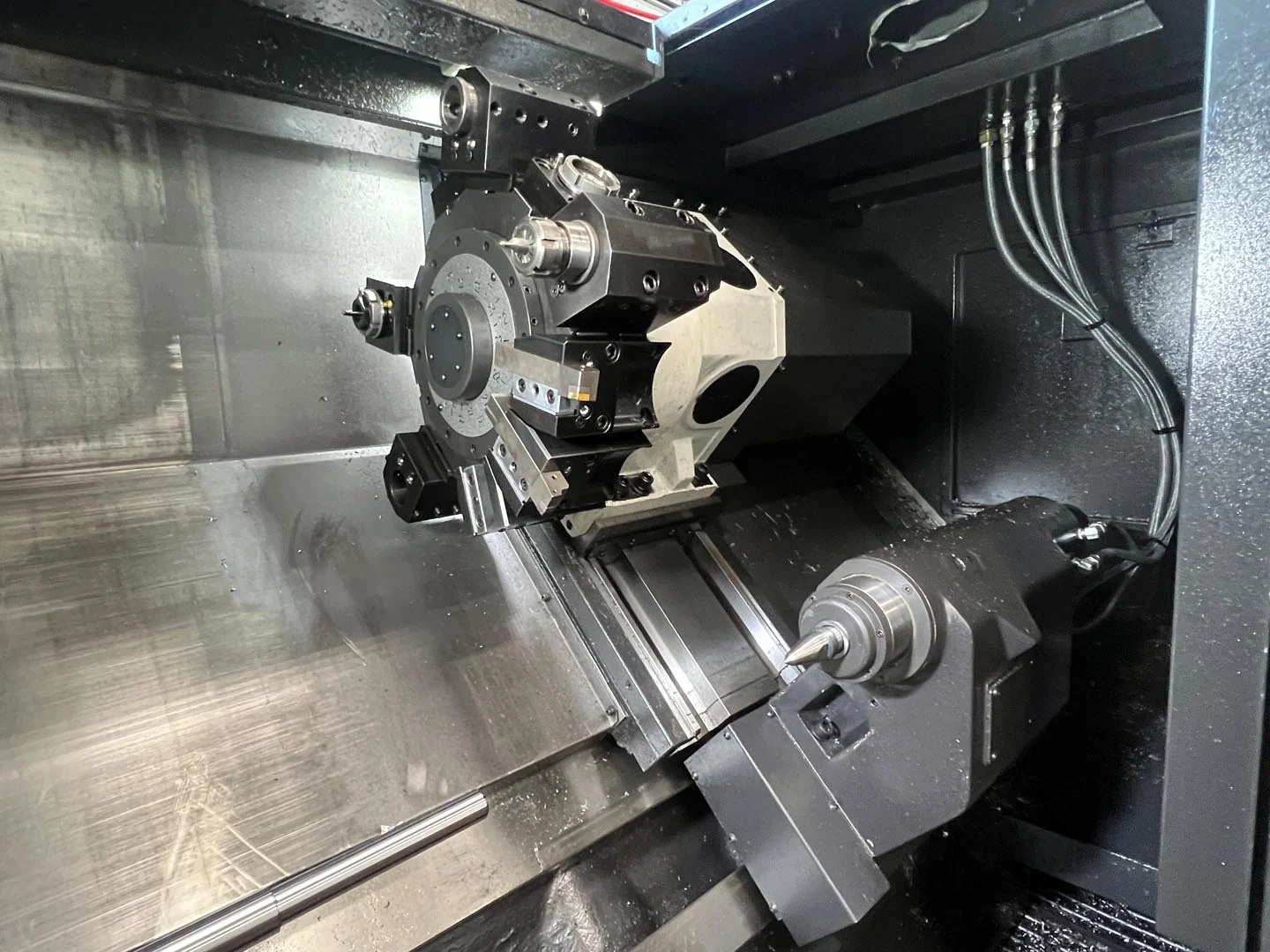

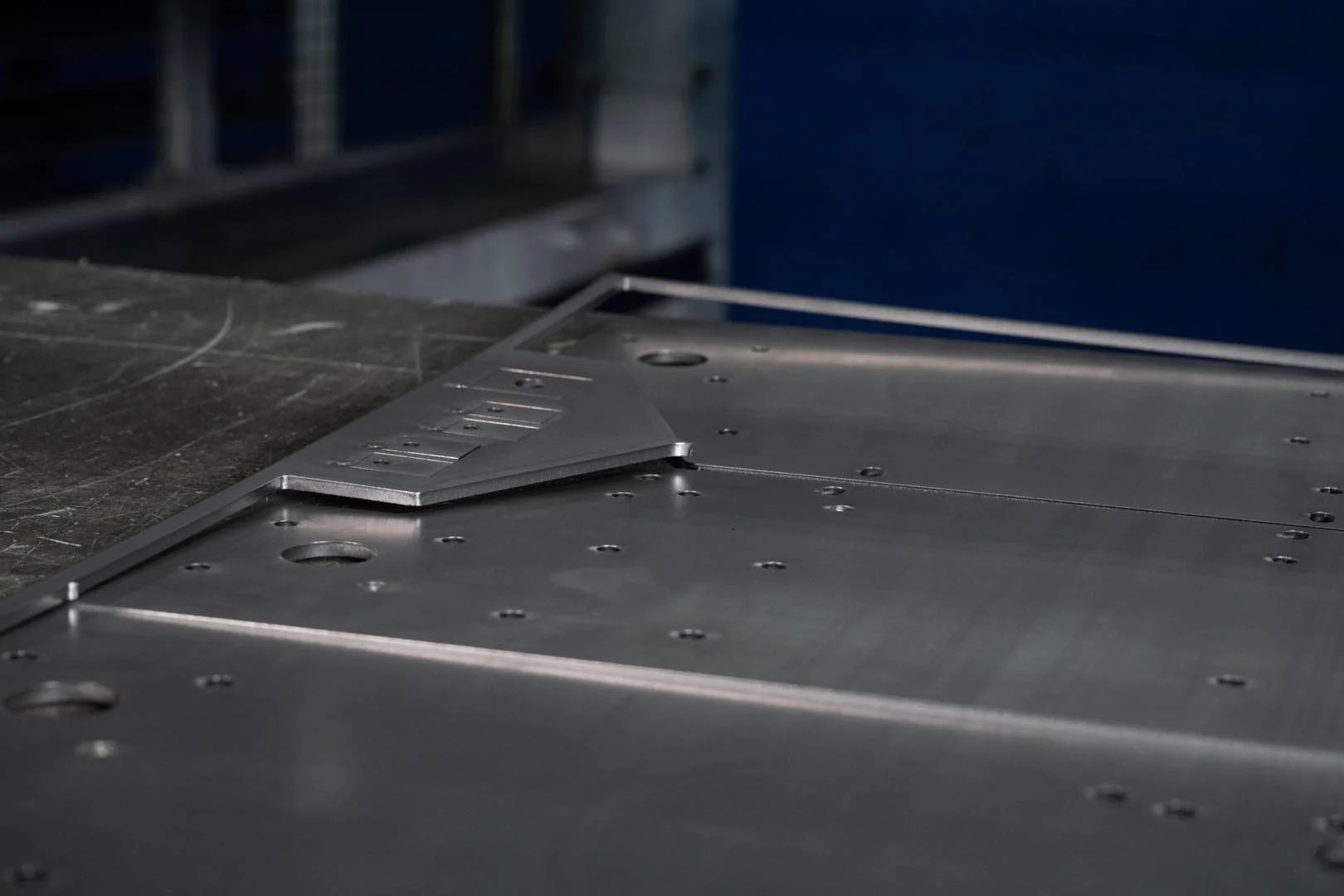

Port Welding’s investment in the high-efficiency Trumpf TruLaser system ensures your projects are executed with unmatched precision and efficiency.

With multiple high-performance machines, we are equipped to handle a wide range of cutting demands efficiently and reliably.

Whether your needs include high-volume production runs, intricate designs, or cutting through thick materials, Port Welding has the expertise and advanced technology to deliver on time, every time.

Let’s take your project to the next level with Port Welding’s expert craftsmanship, custom solutions, and ISO-certified reliability.Port Welding Guarantee of Precision, Quality, and Reliability

Port Welding’s ISO 9001:2015 certification underscores our unwavering commitment to delivering exceptional quality, precision, and reliability for your project. This certification goes beyond industry standards – it forms the foundation of every project we undertake, ensuring we consistently meet your unique needs with the highest level of efficiency and excellence in laser cutting, tube cutting, and brake forming.

Our ISO certification optimizes workflows, reduces waste, and enhances resource management, resulting in faster turnarounds, lower costs, and efficient production. We prioritize customer satisfaction with tailored solutions that meet your deadlines and quality expectations.

ISO 9001:2015 also ensures compliance with safety and industry standards, effective risk management, and continuous process improvement. By working with certified suppliers, we guarantee high-quality materials and maintain transparency and traceability throughout your project.

Exceeding Expectations Across Sectors: How Port Welding Drives Innovation in Manufacturing

Port Welding proudly serves a diverse range of industries, offering precision and reliability with every project. Our expertise extends across sectors, including:

CONSTRUCTION

Delivering precision cuts for structural components and supports that keep your projects on track.

HEAVY EQUIPMENT MANUFACTURING

Cutting through tough materials to produce durable machinery parts for heavy-duty applications.

AUTOMOTIVE

Producing high-quality automotive parts with the speed and precision needed for today’s fast-paced industry.

ENERGY & UTILITIES

Providing reliable cutting and fabrication services for components used in energy production and infrastructure.

CUSTOM FABRICATION

From prototypes to production, we offer tailored solutions for any custom fabrication needs.

AEROSPACE

Crafting intricate, high-tolerance components for the aerospace industry, ensuring safety and performance.

MEDICAL & INDUSTRIAL EQUIPMENT

Producing precision parts for medical devices and machinery that meet strict standards for safety and performance.

No matter the industry, Port Welding’s commitment to excellence, innovative technology, and personalized solutions ensures your project is completed with the highest standards of quality and efficiency.If you're looking for precision, quality, and efficiency in laser cutting or tube cutting, welding, and brake forming, Port Welding positions itself as a trusted partner for your manufacturing needs.